Cookie information

ACCEPT

This site uses only technical cookies, including third-party cookies, and does not use any profiling cookies.

In order to access the site, it is necessary to consent to the use of cookies by clicking on the "Accept" button.

For more information on how we use cookies and how to remove them, see our

cookie policy.

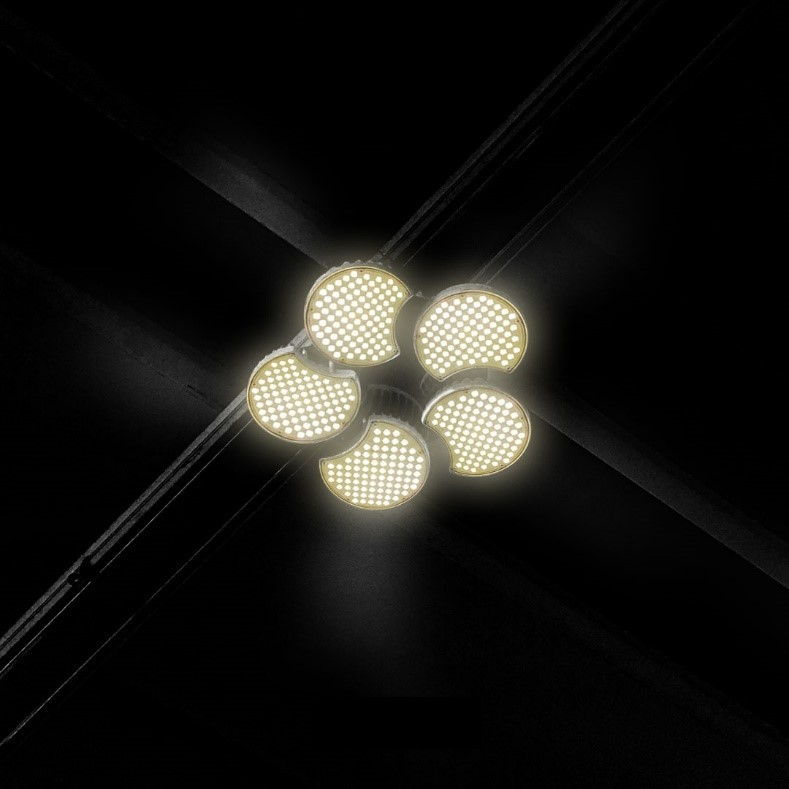

Innovation and precision: how is a lens designed?

Innovation and precision: how is a lens designed?