Electrical engineering and electronicsExplosive atmospheres (ATEX)ATEX is the French acronym for 'ATmosphères EXplosives', which means 'explosive atmospheres'.

The risk arising from explosive atmospheres derives from a concentration of flammable substances such as gas, vapours, mists and dust and their exposure to ignition sources like sparks, electric arcs, static electricity, optical radiation, high temperatures and hot surfaces.

The ATEX 2014/34/EU Directive (relating to protective equipment and systems intended to be used in potentially explosive atmospheres), published by the Official Journal of the European Union (n° OJ EU L96) on 29th of March 2014 and implemented on the 30 March 2014, pursuant to article 43, ratified the repeal of the previous Directive 94/9/CE with effect from the 20 April 2016, without a transitional period. This applies to all electrical and mechanical products intended for potentially dangerous places.

The general requirements for fixtures are outlined in EN IEC 60079-0 that defines the general requirements relating to the manufacture of electrical equipment intended to be used in environments with explosive atmospheres given the presence of flammable gas, vapours, mists and dust.

Classification of explosive atmospheres is carried out based on the recommendations of legislation EN 60079-10-1 (gas), EN 60079-10-2 (dust) that divides dangerous areas into zones based on the probability of the formation and persistence of the explosive atmosphere.

Electrical products must be ATEX certified to be used in environments with dangerous atmospheres.Directive 2014/34/EU classifies and divides ATEX equipment into two groups:

Group I: equipment for work in mines with the presence of mine gas and/or combustible dust is included in this group. Group I in turn is divided into 2 categories:

- M1 - equipment or systems of protection that guarantee a very high level of protection; they must remain operational in the presence of explosive atmospheres.

- M2 - equipment or systems of protection that guarantee a high level of protection; they must be de-energised in the presence of gas.

Group II: equipment for work on the surface is included in this group.

Group II in turn is divided into 3 categories on the basis of the level of protection (area of use); the categories are identified as number 1, 2, 3 followed by the letter G (Gas) or D (Dust).

- Category 1 - equipment or systems of protection that guarantee a very high level of protection; for areas in which explosive atmospheres caused by mixtures of air and gases, vapours or mists or by air/dust mixtures are present continuously, for long periods or frequently. Equipment in this category must ensure the requisite level of protection, even in the event of rare incidents relating to equipment.

- Category 2 - equipment or systems of protection that guarantee a high level of protection; for use in areas in which explosive atmospheres caused by gases, vapours, mists or air/dust mixtures are likely to occur occasionally. Equipment in this category must ensure the requisite level of protection, even in the event of frequently occurring disturbances or equipment faults which normally have to be taken into account.

- Category 3 - equipment or systems of protection that guarantee a normal level of protection; for use in areas in which explosive atmospheres caused by gases, vapours, mists, or air/dust mixtures are unlikely to occur or, if they do occur, are likely to do so only infrequently and for a short period only. Equipment in this category must ensure the requisite level of protection during normal operation.

To summarise:Dust

Gas

1D

Suitability in zones 20, 21 and 22

1G

Suitability in zones 0, 1 and 2

2D

Suitability in zones 21 and 22

2G

Suitability in zones 1 and 2

3D

Suitability in zone 22

3G

Suitability in zone 2

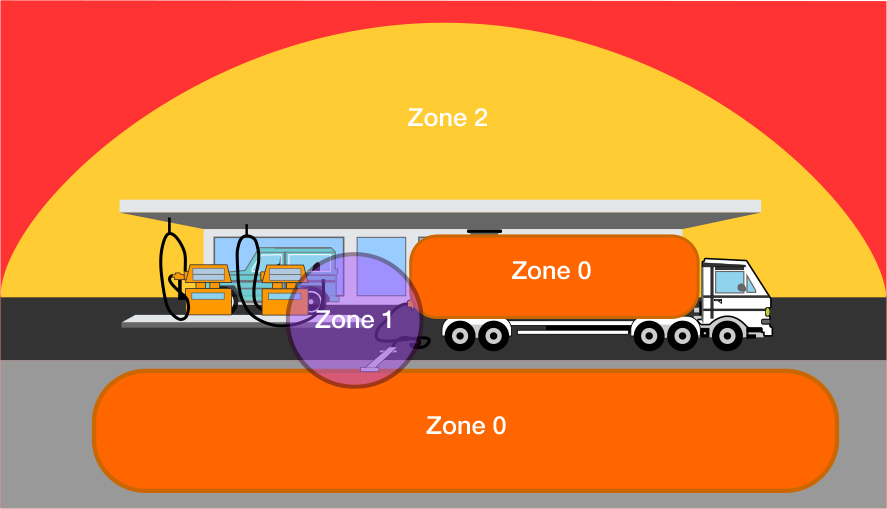

ATEX (G) for zones with GASAreas classified for the presence of gas, mists or vapours on the basis of the probability of the existence of the explosive atmosphere are divided into three zones:Zone 0

Zone 1

Zone 2

An area in which an explosive mixture of gas is continuously present or frequently present for long periods.

An area in which an explosive mixture is likely to occur occasionally in normal operation.

An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time.

Ga: Equipment for explosive atmospheres due to the presence of gas, with a 'very high' level of protection which is not a source of ignition during normal operation or in the event of an expected failure or when subject to a rare failure.

Gb: Equipment for use in explosive atmospheres due to the presence of gas, with a 'high' level of protection that is not a source of ignition during normal operation or when subject to expected malfunctions, although not on a regular basis.

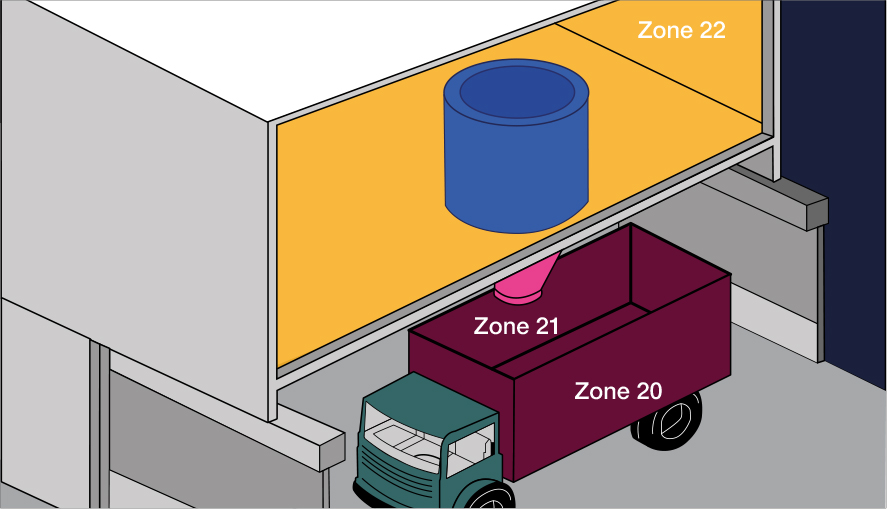

Gc: Equipment for use in explosive atmospheres due to the presence of gas, with an 'increased' level of protection, which is not a source of ignition during normal operation and which has some additional protective measures to ensure that it remains a source ignition not active in the event of regularly expected events (for example for a lamp failure).ATEX (D) for zones with DustIn areas classified for the presence of dust the zones are identified on the basis of the frequency and duration of the formation of an explosive atmosphere:Zone 20

Zone 21

Zone 22

An area in which an explosive mixture of dust in the form of a dust cloud is continuously present or frequently present for long periods.

An area in which an explosive mixture of dust in the form of a dust cloud, is likely to occur occasionally in normal operation.

An area in which an explosive mixture of dust in the form of a dust cloud, is not likely

to occur in normal operation and if it occurs it will exist only for a short time.

From: Equipment for explosive atmospheres due to the presence of combustible dusts, which has a 'very high' level of protection and which is not a source of ignition in normal operation or when subject to rare failures.

Db: Equipment for explosive atmospheres due to the presence of combustible dusts, which has a 'high' level of protection and which does not constitute a source of ignition in normal operation or when subject to expected failures, although not in a regular manner.

Dc: Equipment for explosive atmospheres due to the presence of dust, with an 'increased' level of protection which does not constitute a source of ignition during normal operation and which may have additional protections to ensure that it remains inactive as a source of ignition in the event of faults regular and expected.Compliance proceduresFor equipment to be marked there are various compliance procedures according to the product function and the category they belong to.

- All electrical equipment in Category 1 and Category 2 must mandatorily be certified by ATEX (Notified Bodies), or bodies to which the national authority has assigned the task of verifying conformity with the Directive. Companies that manufacture electrical equipment in Category 1 and Category 2 are obliged to report and audit the quality systems and the identification number of the body must be displayed on the data plate label alongside the CE marking.

- All electrical equipment in Category 3 can be self-certified by the manufacturer (CE marking), with internal manufacturing controls.